Meet Brutus.

The Heavy Lifter.

Revolutionize your warehouse logistics. Brutus is the 600kg payload AMR designed to lift, transport, and organize heavy pallets autonomously with millimeter precision.

600 KG

Max PayloadSLAM

Laser Nav10 Hrs

Runtime

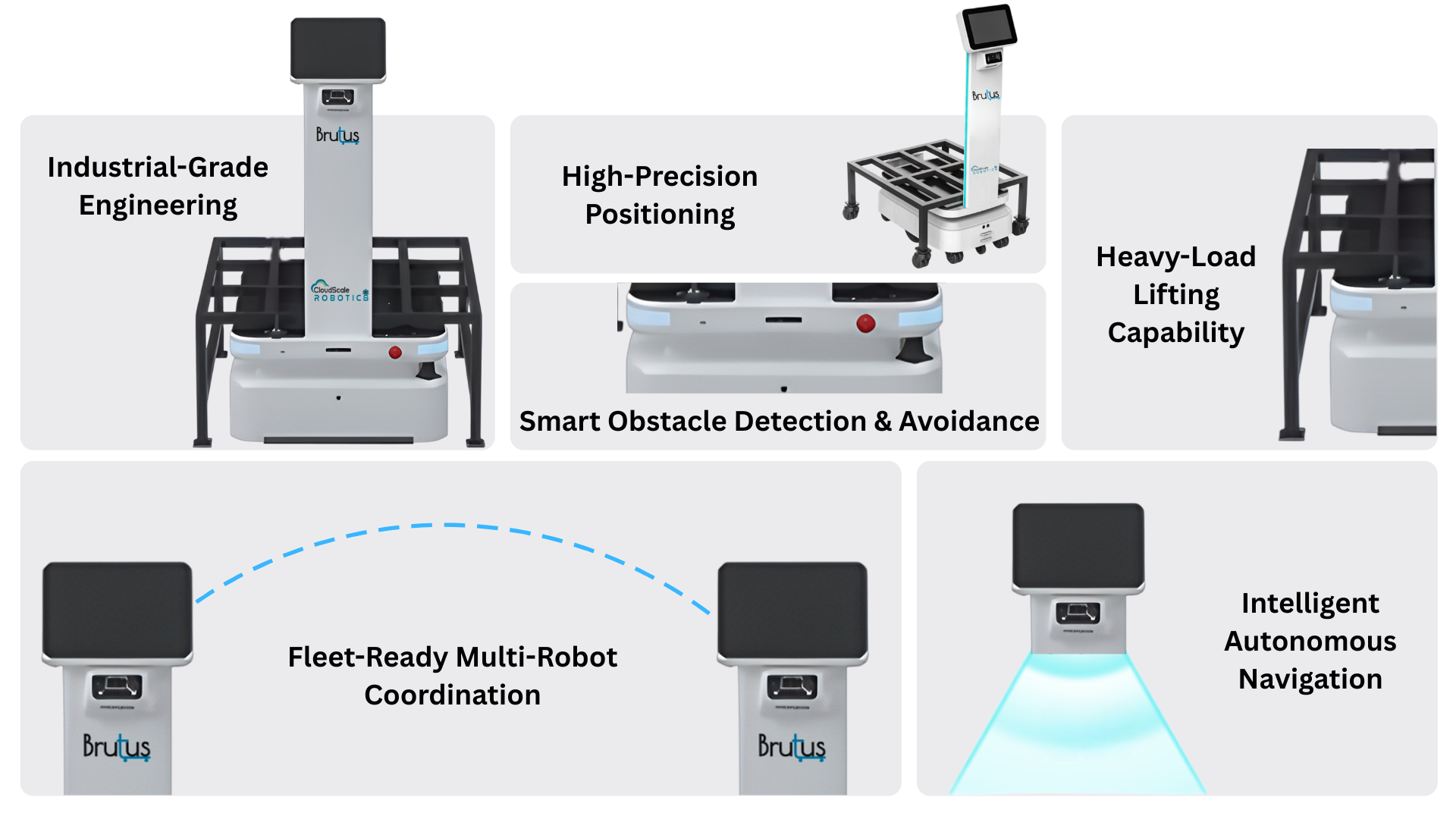

Built for the Toughest Warehouses

Brutus automates material handling with zero infrastructure changes needed.

600kg Payload

Engineered to lift and transport heavy pallets effortlessly. Replaces manual forklifts for repetitive tasks.

Lidar SLAM Nav

No magnetic strips or QR codes required. Brutus maps your facility instantly and navigates dynamically.

360° Safety

Equipped with dual laser scanners and 3D cameras to detect obstacles and stop instantly for human safety.

Swarm Intelligence

Multiple Brutus units communicate to coordinate paths, prevent traffic jams, and optimize workflow.

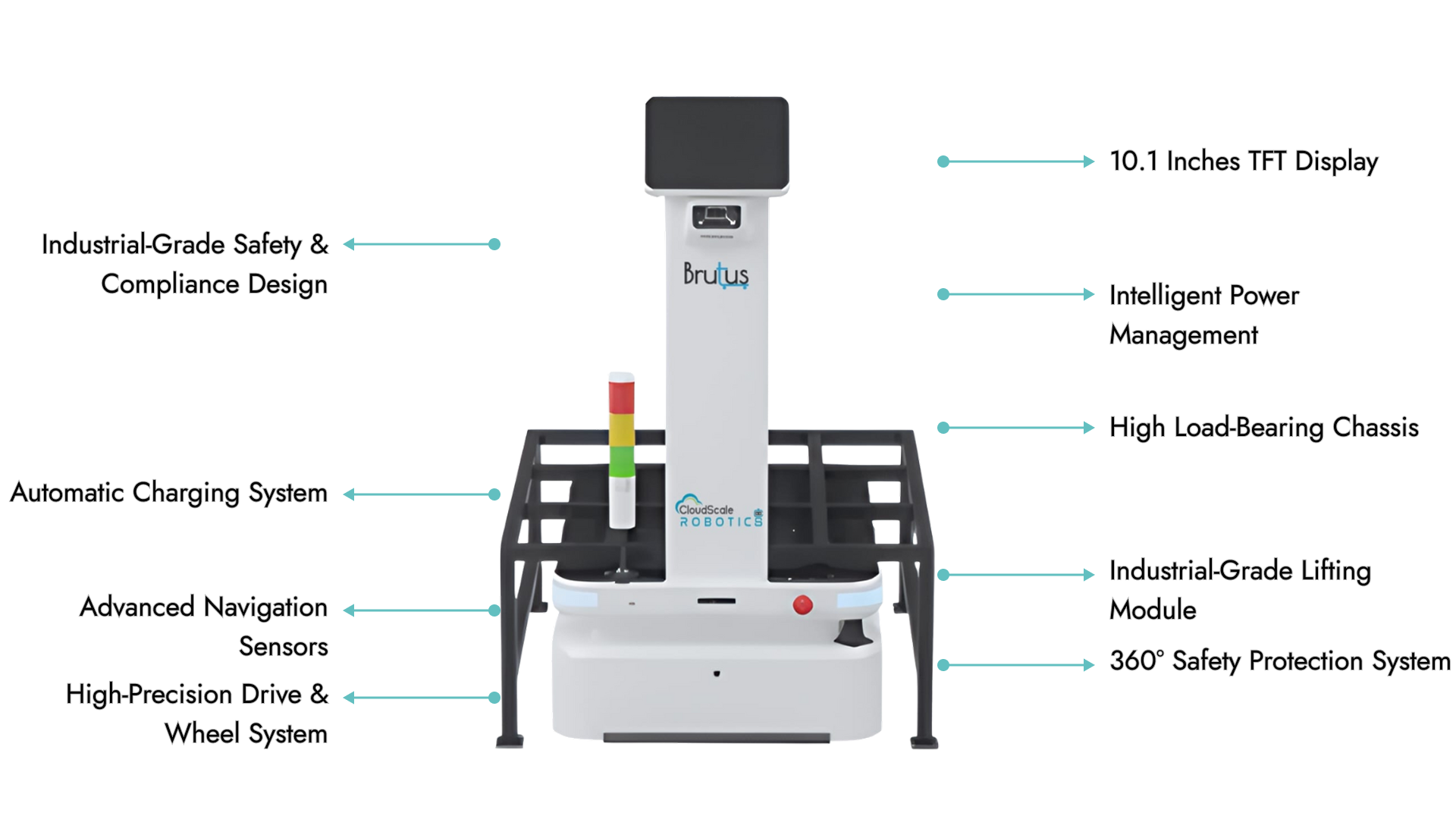

Core Components

Advanced robotics technology for reliable autonomous operation.

Deploy in Minutes.

Run Forever.

Brutus slots into your existing workflow without changing infrastructure. No magnetic tape, no QR codes—just power on and go.

Rapid Setup

Map in < 1 hourLidar Mapping

cm-level accuracyAuto Charge

Returns to dockFleet Sync

4G Connected

Select Your Capacity

From light-duty transport to heavy industrial lifting. All models support RCS scheduling and MES/ERP integration.

B-150

B-300

B-300E

B-600

Engineered for Real-World Chaos

See how Brutus adapts to different industrial tasks, from assembly lines to shipping docks.

Precision Line Feeding

(As seen in image) Brutus integrates directly into active assembly lines. Here, it transports raw material totes (blue bins) to workstations, allowing human operators to stay focused on assembly rather than fetching parts.

- Handles mixed tote sizes securely

- Navigating dynamic human traffic

- Just-In-Time (JIT) delivery

Heavy-Load Outbound Logistics

Once products are packed, Brutus takes over. Capable of carrying heavy stacks of cartons directly to the shipping dock. The integrated cage frame ensures tall stacks remain stable during transport at high speeds.

- Stable transport for tall payloads

- Replaces manual pallet jacks

- Auto-docking with conveyor belts

Multi-Robot Fleet Scheduling

Scale your operations without chaos. Our Swarm Intelligence system coordinates dozens of robots simultaneously (as shown), optimizing traffic flow to prevent congestion in wide transfer areas.

- Intelligent traffic right-of-way

- Prevents gridlock in open spaces

- Centralized dashboard control

Narrow Aisle Navigation

Maximize your storage density. Brutus is designed with a compact footprint to navigate tall, narrow warehouse racking aisles where standard forklifts struggle to fit.

- Centimeter-level positioning accuracy

- Safe operation near static racks

- 360° Lidar mapping of the facility

See Brutus in Action

Watch how Brutus navigates complex facility layouts and handles heavy payloads with ease.

The Backbone of a

Smart Factory

Brutus isn't just a robot; it is a fully connected logistics terminal. It utilizes **Laser SLAM** to map massive facilities without blind spots.

From raw material warehouses to final shipping docks, it unifies traffic control, integrates with elevators, and syncs tasks directly from your WMS server.

Built for Performance

High-precision components engineered for 24/7 durability and safety.

Full Fleet Specifications

Comprehensive performance data for the L-Series lifting robots.

| Feature / Model | B-150 | B-300 | B-300E | B-600 |

|---|---|---|---|---|

| Physical Dimensions & Capacity | ||||

| Max Load Capacity | 150 kg | 300 kg | 300 kg | 600 kg |

| Dimensions (mm) | 740×500×1240 | 740×500×1240 | 900×600×1240 | 950×650×1240 |

| Loading Area (mm) | 700×600 | 700×600 | 940×810 | 940×810 |

| Vehicle Weight | 76 kg | 85 kg | 90 kg | 100 kg |

| Min. Passage Width | 70 cm | 70 cm | 80 cm | 80 cm |

| Performance & System | ||||

| Maximum Speed | 1.2 m/s (Adjustable safety limits) | |||

| Navigation Method | SLAM (Laser) / Hybrid / Trackless / Follow Mode | |||

| Positioning Accuracy | ± 10 mm | |||

| Battery & Charging | 12h Operation / 5h Charging time | |||

| Interface | 10.1 Inch HD Touchscreen | |||

| Communication | 4G / Wi-Fi / LoRa | |||

| Certifications | CE / FCC / KC / NCC / EMC | |||